High or low pressure pumps: which choice suits your painting process?

The pump determines stability and efficiency

The pump is the heart of your painting process. It controls stability, efficiency and consumption. TLCA.be makes the right match between pump, application and coating.

Low pressure vs high pressure: when do you choose what?

Low-pressure pumps (up to approx. 20 bar)

Constant supply with fluid pressure regulator and a fine, even spray. Ideal for thin layers and high aesthetics. Read more about low-pressure atomisation.

High-pressure pumps (approx. 50-500 bar)

For Airless or Air Assisted Airless, high production speed and high-viscosity coatings. More about high-pressure atomisation.

Hybrid approach

Combine where useful: high pressure for primers and filling systems, low pressure for top coat or detail areas.

TCO: speed, finish and maintenance

Balancing costs

High pressure is faster, but parts are under higher stress. Low pressure takes longer per part, but can reduce post-treatment by providing a tighter finish. The best choice depends on product, layer thickness, finish, production speed and maintenance regime.

TLCA selection and adjustment

From pump to process

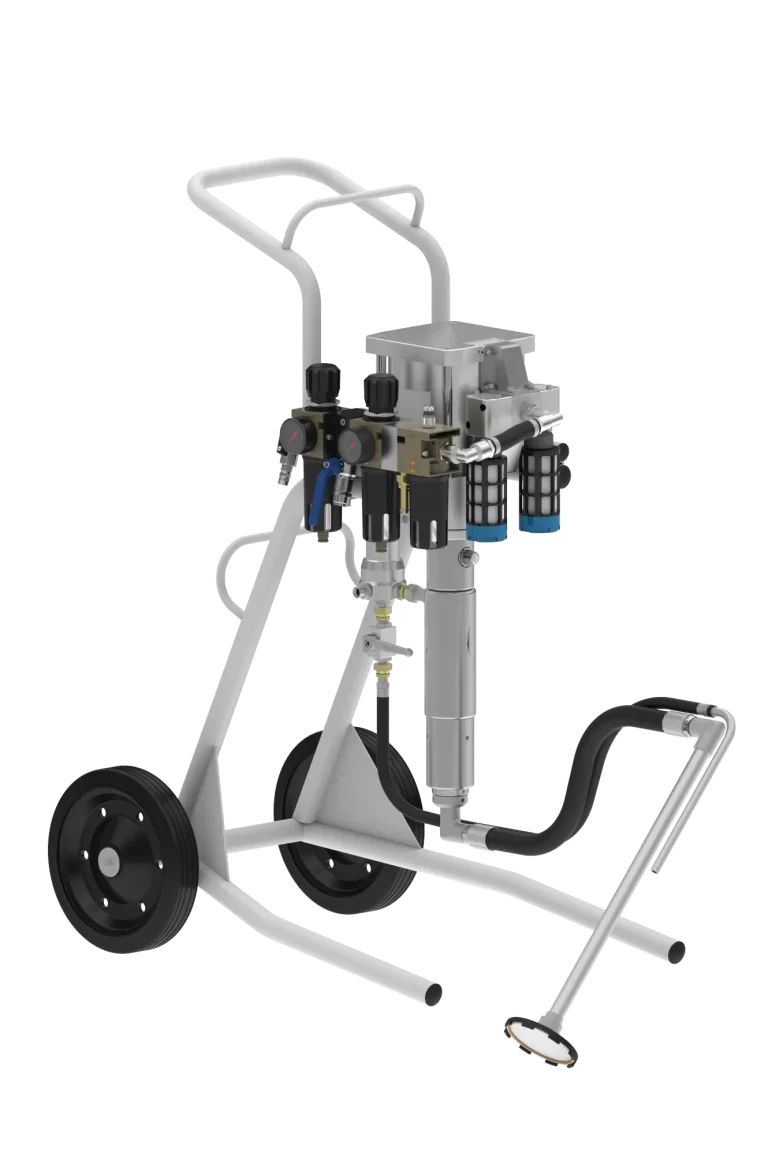

We select and set the right configuration: pump type and ratio, regulators and filters, hose bundle and gun. With tailor-made trainings guarantee your safety, layer thickness control and consumption. Ready for a quick process check? Contact us or discover more in TechTalk.

More info?

Dürr: Pumps and Fluid Handling

Overview of low- and high-pressure pumps for paint supply and circulation in industrial painting processes.

Choose low pressure for finesse and finish, high pressure for speed and high-viscosity coatings. TLCA helps you select and adjust, keeping quality and consumption under control. Plan your process check.