From manual work to automation: How TLCA offers real solutions in spray application

VOMinfo magazine - issue 04-2025

Manual varnishing will always have a place in the industry. No robot can replace the finesse and flexibility of an experienced sprayer completely replaced. But reality is changing: processes are becoming more complex, quality standards are rising and experienced professionals are becoming scarcer. Automation then seems to be the only solution. Yet it is not feasible or even desirable for every company to switch to a fully automated process in one leap.

Demand-driven

The reality in the workplace

Many manufacturing companies continue to rely heavily on manual spray application. Rightly so, because not every product or production volume lends itself to an automated process. Moreover, there is a form of craftsmanship in manual spraying that you don't simply replace with a machine. Yet there are clear challenges:

- Quality consistency: results may vary depending on the operator, day and conditions.

- Staff pressure: finding young employees willing to learn the trade is no easy task.

- Losses: colour changes, start-up losses and waste remain a cost for companies.

TLCA offers support here with concrete, realistic interventions. Think of ergonomic workplace designs that reduce the physical strain for the sprayer, optimisation of spray gun selection and settings, training and guidance on streamlining the spraying process itself. Small interventions that often have a big impact on daily work.

Gradual guidance towards automation: not an all-or-nothing story

Automation is often presented as a necessary revolution. But at TLCA, we believe more in evolution. For many companies, the step to full automation is too big, too expensive, or simply unnecessary. That is why we guide companies in making the right choices, tailored to their specific needs:

- What could be simpler today?

- Where is the bottleneck?

- Which processes are better left manual, or which can be automated?

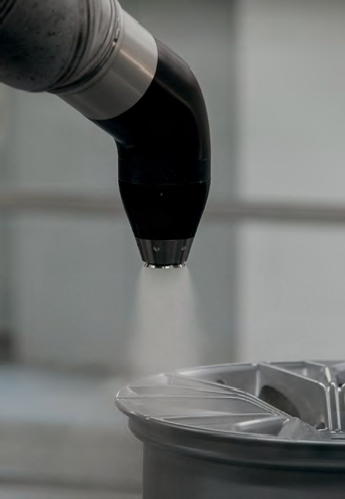

Inspiration: electrostatic spraying in the wood industry and high-pressure atomisation (airless & AAA).

Dosing: 2K/3K systems that work for the shop floor

Another crucial factor in the application process is the dosage of paint products. Inaccuracies in mixing ratios lead not only to quality problems, but also to wasted material and time.

TLCA offers and installs 2K/3K dispensing systems that:

- mixing products exactly at the time of purchase;

- minimise rinse losses thanks to optimised colour change procedures;

- provide flexibility for different product types and applications; and

- relieve the operator of error-prone manual mixing processes.

Want to know more? Take a look at our practical training modules and product-related updates such as Dürr EcoGun ACE.

The paint kitchen: the heart of efficient spraying

In many companies, the paint kitchen - the area where products are mixed, prepared and managed - is underestimated in its impact on the overall process. TLCA sees this area as the beating heart of the paint application.

What does a good paint kitchen deliver?

- logical flow from product storage, mixing to off-take;

- ATEX-compliant installations that are safe and practical;

- Optimisation of colour change procedures to minimise time and product loss;

- clear work zones that reduce the workload for the operator.

Our approach does not start from a theoretical ideal, but from the reality of the shop floor. How can the existing space be optimised? What is needed to make work processes run more smoothly? That is the approach with which TLCA designs and implements paint kitchens. Read also: ATEX & Machinery Directive at spray plants.

Automation is not an end in itself

At TLCA, automation is not the end point, but a logical consequence of a well-optimised basic process. It makes little sense to deploy a robotic arm if the spray booth, dosing or paint kitchen are not on point. That is why we guide our customers step by step, from a realistic view of their processes and possibilities.

Whether it is about optimising manual application, integrating a 2K/3K dosing system, or redesigning the paint kitchen, the basics have to be right. Only then does automation become an investment that really pays off.

Continue reading? Discover more articles on TechTalk or delve into topics such as RSI prevention in paint spraying and B-TEC solutions for the paint shop.