The spray application in flatbed sprayers: how does it work and what to look out for?

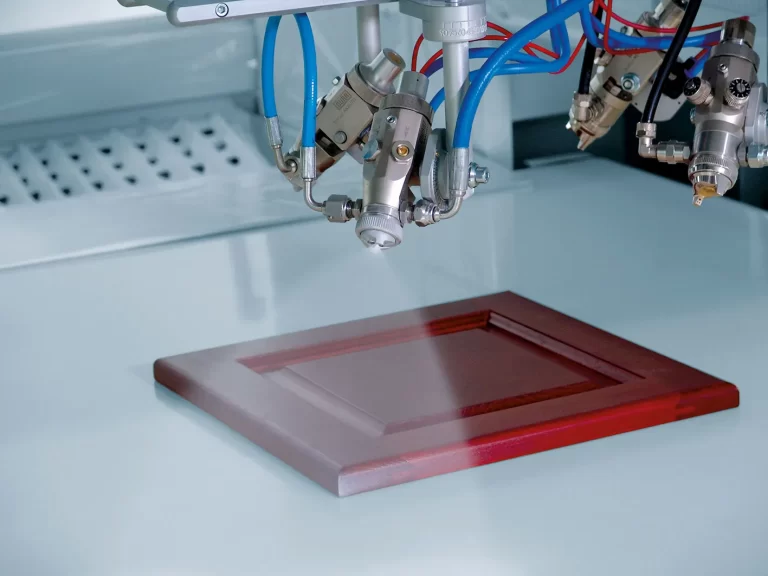

In flatbed spraying machines, wooden workpieces on a conveyor belt automatically pass through a spraying zone. Above this zone, spray arms move perpendicular to the direction of transport. Thanks to scanners that detect each workpiece, paint is applied only where needed - efficiently and without waste.

Gun types & atomisation technology comparison

The nozzles in these machines use technologies such as:

- Low pressure: Fine atomisation, suitable for lacquers, stains and metallics.

- Air Assisted Airless: Higher output, ideal for primers, fillers and thicker coatings.

The right choice depends on paint type, desired finish and production flow rate. Parameters such as paint pressure, spray pressure and spray angle directly influence paint quality.

Automatic colour change and cleaning

Modern systems have automatic rinsing programmes. These enable fast colour changes without manual intervention - even during small production batches. Multiple circuits ensure a seamless transition between different paint types without a production stop.

Importance of correct settings and maintenance

Optimal results require accurate settings and regular maintenance. Think about cleaning guns and filters, but also calibration of the scanner technology. This is the only way to maintain quality in the long term.

Want to know more about wood finishing?

- Your partner in perfect wood finishing

- Electrostatic spraying in the wood industry

- EcoGun ACE: precision and efficiency for timber industry

Ready to optimise your paint process?

Mail us! for a free technical scan tailored to your production process.

Quality, reproducibility and safety

Flatbed sprayers offer numerous advantages:

- Constant layer thickness and uniform finish

- Reproducible results regardless of operator experience

- Reduced emissions thanks to controlled atomisation

- Improved working conditions through enclosed cabs and extraction

The key to success lies in a perfectly tuned application and regular maintenance.