Low-pressure atomisation

When applying paint or coatings, there are several techniques that affect effectiveness, speed and precision. One is low-pressure atomisation, a technique in which paint or another liquid is applied via an air nozzle. This technique is especially popular for spraying thin layers and for applications that require higher control and finish.

What is Low Pressure Nebulisation?

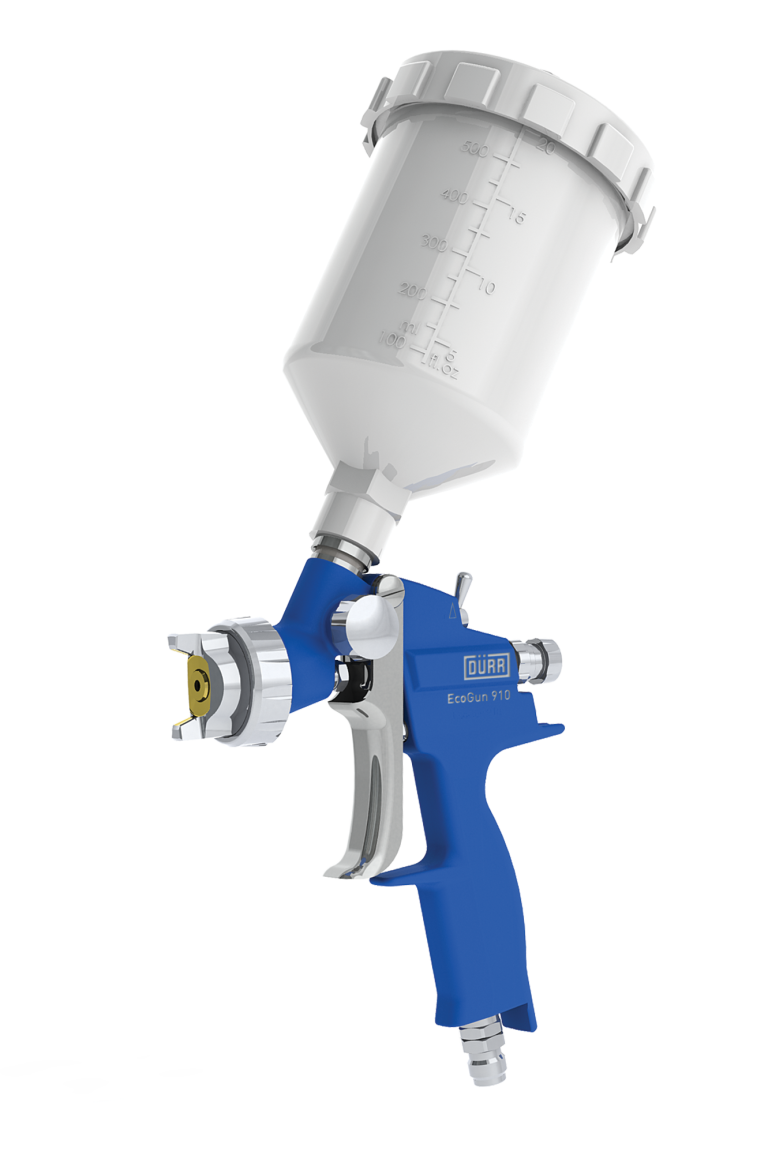

Low-pressure atomisation is a spraying technique in which paint or another liquid is fed through an orifice in the spray gun. The paint is supplied by means of gravity, negative pressure or a pump or pressure vessel. After the paint is passed through this opening, it is compressed air sent along to blow the paint jet apart and create a fine mist. This technique ensures that the paint is distributed finely and evenly over the surface, and the air flow ensures that the paint is applied to the object in a controlled manner.

The main advantage of low-pressure atomisation is the accuracy with which you apply the paint, and the ability to make the paint flow and the beam width adjustable for the desired finish. This makes it an excellent choice for finer applications where a high level of precision is required.

With the ability to control paint flow rate and jet width, low-pressure atomisation offers a high degree of control, resulting in a more consistent finish and less wastage of paint.

Advantages of low-pressure atomisation

Low-pressure atomisation has several advantages that make it an attractive choice for many different applications:

- Better control and accuracy: The ability to adjust the paint flow rate and beam width allows paint sprayers to better tailor the application to the requirements of the job, resulting in a precise and consistent finish.

- Cost-effective: The ability to regulate paint flow and air supply means less paint is wasted, reducing costs, especially on larger projects.

- Smooth Finish: The technique is ideal for applying thin, even layers that require a smooth and attractive finish.

Applications of Low Pressure Nebulisation

Low-pressure atomisation is often used in applications where accuracy and high finish quality are essential. Some common applications include:

- Lacquering of furniture and interiors: When spraying furniture or interior products it is important that the paint is applied evenly and without visible splashes. Low-pressure atomisation creates a fine mist that creates a smooth, professional finish delivers.

- Decorative coatings: For decorative paint systems or applying colour changes on objects, low-pressure atomisation offers the possibility of creating controlled effects without wasting paint.

- Car and yacht varnishes: In car painting or yacht painting, where precision and a high degree of finish are required, low-pressure spraying is often used. The technique makes it possible to apply a thin, even layer of paint.

- Garden furniture and exterior finishes: When varnishing outdoor furniture or other outdoor applications, low-pressure atomisation can help create a durable and protective coating apply.

Adjusting spray width and paint flow rate

One of the biggest advantages of low-pressure atomisation is the ability to increase the beam width and the paint flowadjust accurately. This makes the technology extremely versatile, as it is possible to:

- Smaller surfaces very detailed and can be handled with less paint.

- Larger surfaces quickly and efficiently provide an even coat of paint.

This makes low-pressure atomisation suitable for both detailed work as for larger projects, depending on the needs of the job.

Low-pressure atomisation is an efficient and precise spraying technique ideally suited to applications where control, reduced wastage and a beautiful finish are essential. Whether you are applying furniture, vehicles or decorative coatings, the ability to adjust paint flow and spray width makes this technique versatile and cost-effective.

Want to know more about the technology and equipment that makes low-pressure atomisation possible? Contact us for advice and the right spraying technologies for your projects!