How an automation project reduces 30% solvent consumption

Reducing rinse agent consumption at colour changes

Why rinse aid is a strategic process choice

Rinse agent consumption is an underestimated cost item in many paint shops. Not spectacularly visible, but structurally present.

Especially with frequent colour changes and 2K/3K applications, consumption increases quickly. Therefore, it pays to look at paint supply and dosage as a whole.

Reducing rinse agent consumption at colour changes

Rinse agent consumption is an underestimated cost item in many paint shops. Not spectacularly visible, but structurally present. Especially with frequent colour changes and 2K/3K applications, consumption quickly increases.

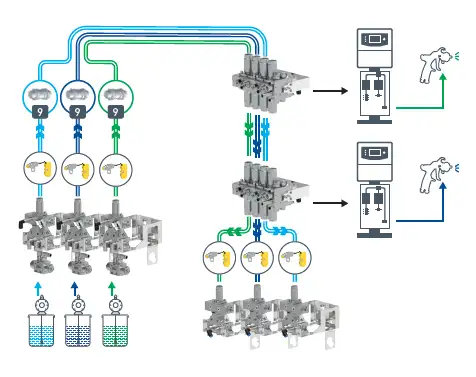

EcoSupply P Core and EcoDose 2K/3K

The combination of EcoSupply P Core with EcoDose 2K/3K addresses just that pain point at the system level. Also read: EcoSupply P Core optimises colour changes in the paint line and 2K and 3K dispensing technology for paint processes.

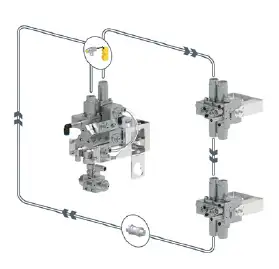

With the pigging technology of the EcoSupply P Core, the paint remaining in the lines during a colour change is not washed away, but mechanically pushed back to the source. That means: less residual paint in the line before the rinsing phase starts. Less residual paint in the line automatically means less rinse agent needed to achieve a clean transition.

Couple this with an EcoDose 2K/3K system, and the effect becomes even clearer. Because the mixing is done only shortly before application and the mixed volume is greatly reduced, you also limit the amount of reactive lacquer that has to be rinsed out. So you don't flush metres of pipe with mixed material, but only a minimum mixing volume. Practicality: tailor-made paint application training courses also elaborate on this.

Results in practice

- significant reduction in rinse agent consumption

- less waste of mixed 2K/3K varnish

- shorter colour change times

- more stable and reproducible processes

More importantly, this is not a single component optimisation in isolation. It is an integrated approach to paint supply and metering. Chasing less chemistry through the line, creating less waste and still maintaining maximum process control. Find more context at TechTalk on paint processes and spraying techniques.

In times when material prices, environmental pressure and downtime costs are only rising, efficient use of rinse agent is no longer a detail. It is a strategic choice in your coating process. Questions or checkout on your line? Contact TLCA.

Briefly: Rinse agent consumption often increases with frequent colour changes and 2K/3K applications. EcoSupply P Core (pigging) mechanically pushes back residual paint, requiring less rinse agent for a clean transition. EcoDose 2K/3K limits mixed volume to just before application, further reducing waste and rinse time.

Source: TLCA (tlca.be).

FAQ

1) Why does rinse aid consumption rise quickly during colour changes?

Because frequent colour changes require more rinse cycles and residual paint in pipes requires additional rinse agent.

2) What is the effect of pigging at EcoSupply P Core?

The paint in the pipes is not washed away during colour change but pushed back, leaving less residual paint before the rinsing phase.

3) Why does EcoDose 2K/3K help extra with rinsing?

Because the mixing is done only shortly before application and the mixed volume remains small, less reactive lacquer has to be washed out.

Sources

By reducing residual paint in lines before the rinse phase and creating the mixed 2K/3K volume only just before application, rinse agent consumption decreases and mixed paint waste decreases. This supports shorter colour changes and more stable processes.