Process optimisation doesn't start at the gun

Process control starts before application

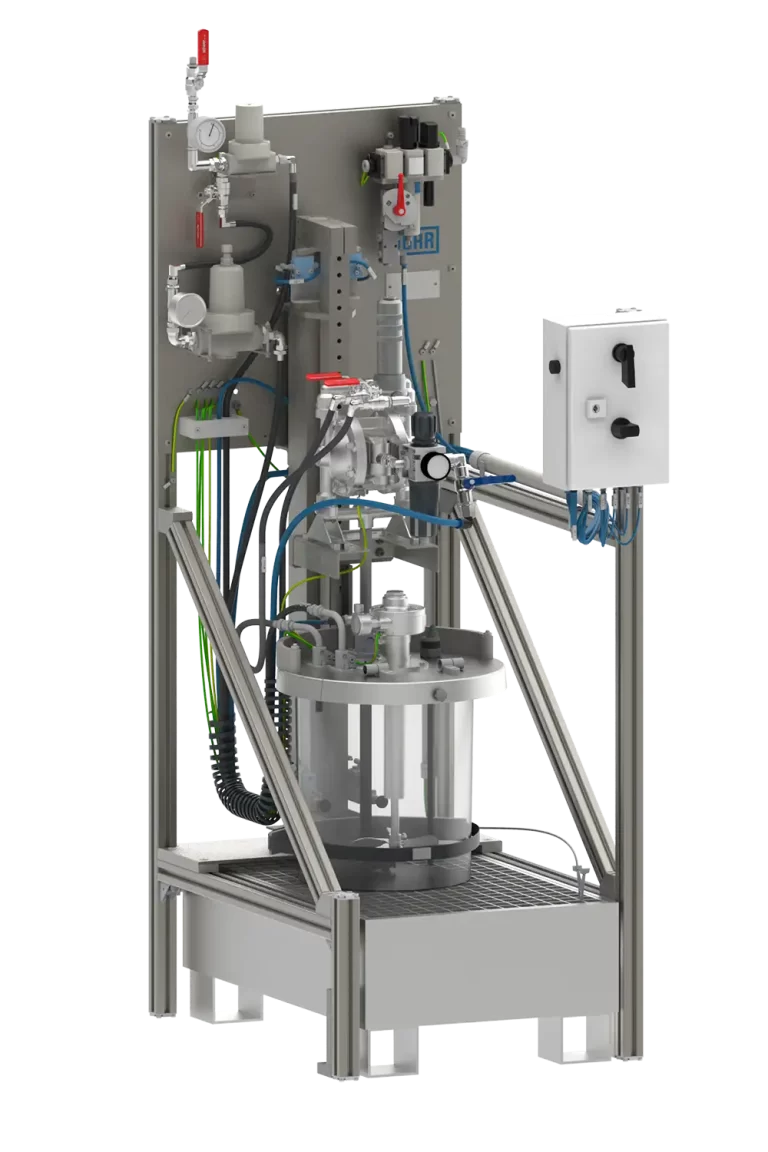

In industrial paint application, spraying, robotisation or gun technology is often considered. But the real stability of your process is determined before the paint reaches the gun.

Those who control paint supply and dosing lay the foundations for a stable spray pattern and reproducible quality.

Process optimisation doesn't start at the gun

In industrial paint application, we often look at atomisation, robotisation or gun technology. But the real stability of your process? That is determined before the paint reaches the gun. (See also advice on the right application technology.)

What causes a poorly sized paint supply?

- pressure fluctuations

- varying layer thicknesses

- more overspray

- faster wear

In 2K and 3K systems, there is an additional factor: a small deviation in mixing ratio can already lead to poor curing or rejection. (More context: 2K and 3K dispensing technology.)

Correct paint supply + precise dosage =

- ✔ stable spray pattern

- ✔ reproducible quality

- ✔ less material loss

- ✔ more process security

A system that “works” is not automatically a system that works optimally. Those who do not control their paint kitchen are optimising at the wrong end of the process. (Practical: paint application training and select high or low pressure pump help secure that foundation. You can find more articles at TechTalk.)

# paint application #2K # process optimisation # paint kitchen # industrial coating

Briefly: Process stability in industrial paint application is often determined before the paint reaches the gun. Poor paint supply and small ratio deviations in 2K/3K can lead to pressure fluctuations, quality variation and rejects. Correct paint supply and accurate metering support a stable spray pattern, reproducible quality and reduced material loss.

Source: TLCA (tlca.be). Contact: contact us.

FAQ

1) Why doesn't process optimisation start at the gun?

Because the stability of the process is already determined by paint supply and dosing before the paint reaches the gun.

2) What are typical consequences of a poorly sized paint supply?

Pressure fluctuations, varying layer thicknesses, more overspray and faster wear.

3) Why is dosing extra critical in 2K and 3K systems?

Because even a small deviation in mixing ratio can lead to poor curing or rejection.

Sources

Process stability is strongly influenced by paint supply and dosage before application. By controlling that basis, you reduce pressure fluctuations, quality variation and risk of rejection in 2K/3K.