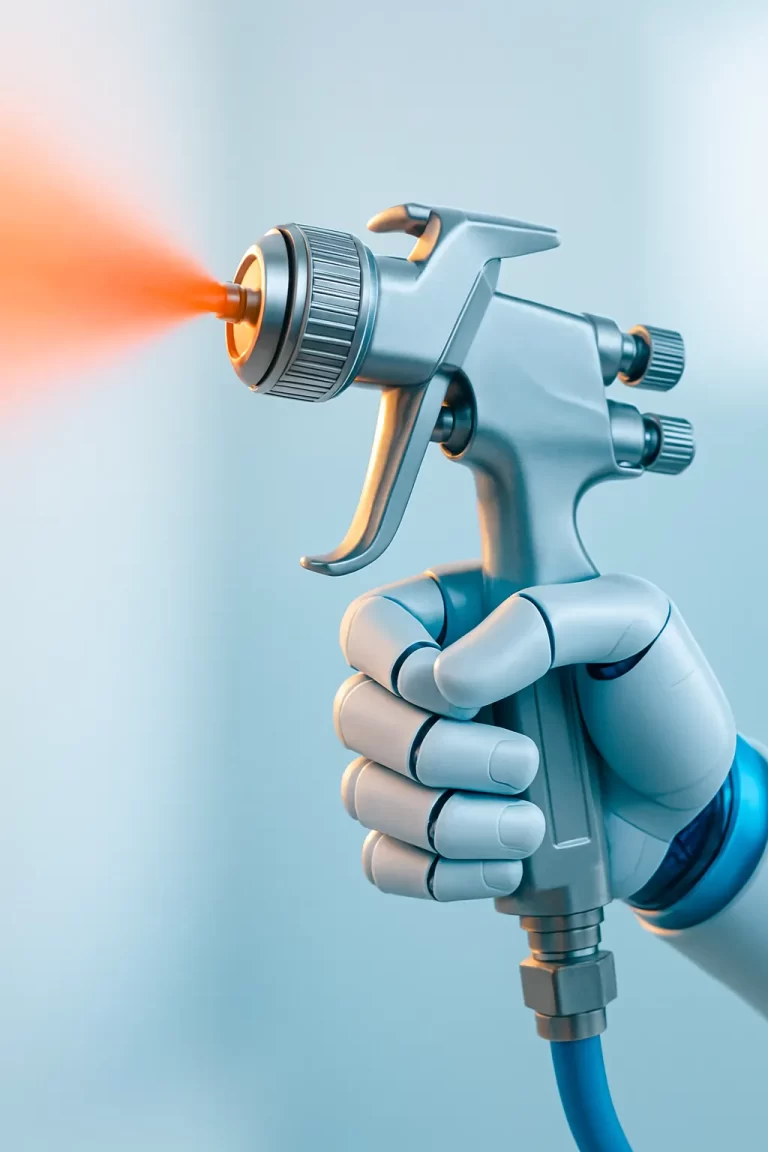

Automation in the Coating Industry: current state & future prospects

The coatings industry is not standing still. Automation offers huge opportunities to work more efficiently, consistently and sustainably. But where are we today? And how do you start such a journey as a company? In this article, you will discover the current state of affairs, the challenges as well as the technological prospects - with practical tips on how to automate step by step.

Where do we stand today?

Mechanical automation: conveyors & CNC guns

Conveyors and gun movements with repeaters or CNC control are the basis of mechanical automation in the coating industry.

Robotic applications in large series

6-axis robots perform repetitive tasks, especially in industries such as automotive or furniture panels. Read more about robotics at TLCA.

2K/3K dosing technology: precise and real-time

These systems ensure exact mixing ratios, real-time logging and reduced waste. They are a smart first step towards automation.

Monitoring with sensors

Advanced sensors measure flow, pressure, temperature and viscosity for a stable and controllable process.

Electrostatic spraying: efficiency and challenges

With electrostatic spraying, you reduce paint loss, provided the grounding and substrate are perfect.

Bottlenecks that automation must solve

Product geometry and small series

Not every product is a straight cabinet door. Variable geometries and small batch sizes make automation more complex and expensive.

Maintaining expertise

A manual sprayer with 30 years of experience is difficult to replace with a robot. Therefore, human expertise remains crucial.

Investment versus batch size

For small runs, the ROI on expensive robots is often limited. Semi-automatic systems offer a solution here.

ATEX compliance

ATEX regulations do not make it obvious to integrate any technology just like that. Read more about ATEX at TLCA here.

Future prospects

Vision AI & Machine Learning

AI systems automatically recognise product shapes and adjust spray settings in real time. Read how TLCA works with AI.

Digital twin of coating process

Virtual simulations and adjustments make it possible to predict maintenance and optimise processes.

Self-learning spray robots

These robots use feedback loops based on measured layer thickness, temperature and deviations to adjust themselves.

Integration with MES/ERP

Thanks to links with MES/ERP systems, production processes can be automatically adjusted based on orders and stock levels.

How do you start with automation?

Process analysis & inefficiencies

Analyse the current workflow and detect where waste, errors or deviations occur. See how TLCA helps you do this.

Semi-automatic mixing systems

Start with scalable solutions that maintain control and build efficiency.

Scalable systems (Dürr)

Dürr's ready2integrate solutions are modular and perfect for growing production needs. Read more about Dürr at TLCA.

Training & maintenance

A good automated system stands or falls with technician training and a proactive maintenance plan.

What does this mean for your business today?

- Start small with, for example, 2K dosing or automatic rinse cycles.

- Training and further education remain essential.

- Collaboration between humans and machines is the key to success.