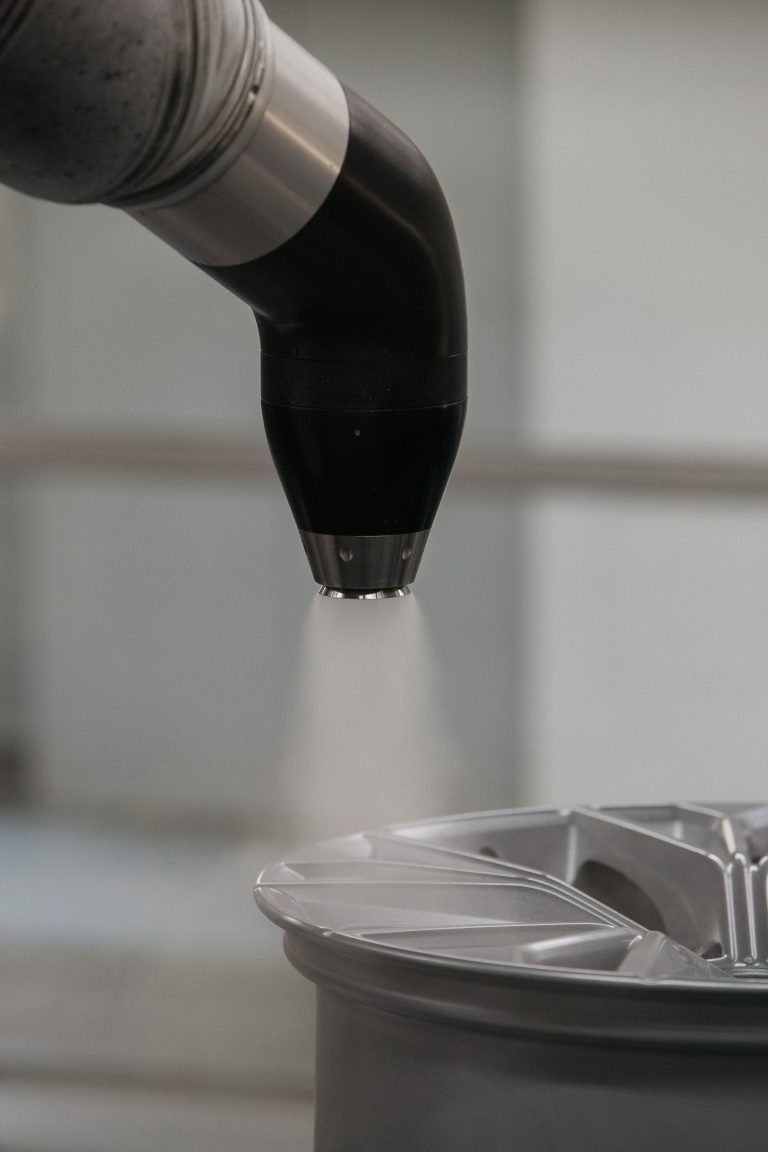

Rotational Nebulisation or bell application: A Revolutionary Spraying Technique in Modern Industry

Rotational atomisation has taken an important place in industrial paint processes in recent years. This innovative technique offers unique advantages that set it apart from traditional spraying methods.

Operating principle

At the heart of this technology is the rotating disc or 'clock' that spins at impressive speeds of between 10,000 and 100,000 rpm. When the paint hits this disc, it is atomised into microscopic particles by the centrifugal force. A controlled airflow then directs these paint particles towards the workpiece.

Advantages over conventional spraying methods

-

Superior efficiency

-

Less overspray than with traditional spraying techniques

-

Lower paint consumption, saving costs

-

Better coverage in hard-to-reach corners and edges

-

-

Improved quality

-

Very even paint layer

-

Excellent surface quality

-

Minimal chance of drop formation

-

Applications

Automotive & Truck & ACE industry

-

Body parts

-

Trailers

-

Interior parts

-

Rims

Furniture industry

-

Office furniture

-

High-gloss

-

Designer furniture

Industrial applications

-

Machine parts

-

Electronics enclosures

-

Medical equipment

Future prospects

Technology continues to evolve with new innovations such as:

-

Digital control systems for even more precise application

-

Environmentally friendly systems with even less overspray

-

Integration with robotics for fully automated production processes

This spray technology is proving itself as a sustainable and efficient solution for modern industrial paint processes, especially in sectors where quality and efficiency are paramount.

Rotary Atomisation offers benefits such as higher efficiency, less overspray and lower paint consumption. It ensures an even paint film and is ideal for industries such as automotive, furniture and mechanical engineering. With continuous innovations, such as digital control and robotics, this technology remains a sustainable and efficient solution for high-quality paint processes.